Summary

I've enjoyed designing since I was exposed to the subject in high school and taught myself how to CAD with Fusion 360 (and later OnShape and SolidWorks too) to visualize my ideas and honestly, because I enjoyed it. Here are a few personal designs that I'm especially proud of from over the years.

The projects in order here are

06_Cigar Cutter

5/28/2019

This was one of my first projects, a gift for my dad's friend. It was good practice for understanding the role of components and the basics of joints.

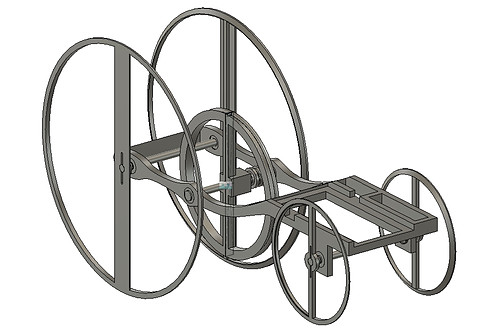

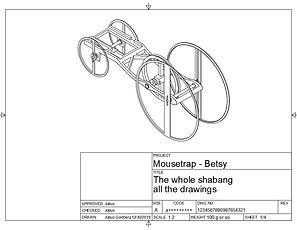

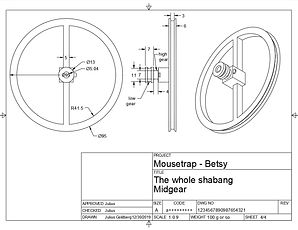

20_Mousetrap Car

12/2/2019

Part-By-Part Animation

This mousetrap car was my submission for a project for honors physics sophomore year of high school. I believe I quadrupled the past record, making it 86 meters (the length of the gymnasium, back, and a little change) and getting a 455% on the project through extra credit.

For my submission, I needed to include a description of the vehicle, so it was the perfect opportunity to learn how to create animations and produce technical drawings in Fusion 360.

Technical Drawings

23_Compound Elevator

12/22/2019

Retracted Elevator

Partially Extended Elevator

Fully Extended Elevator

The compound elevator has multiple internal frames, which rise together with the pull of a single cleverly threaded wire. Its simplicity and compactness made it an attractive mechanism to explore for the First Robotics Competition.

Through designing this I learned how to design sliding movement and link the operation of multiple joints.

30_Wrist-Mounted Slingshot

4/2/2020

The wrist mounted slingshot was printed out of PLA and functioned decently, but was too brittle to accomplish much. After some research, I learned more about the properties of different materials and became more interested in printing with different materials like PETG, Nylon, and even carbon fiber infused filaments.

46_Sanding Tool

12/2/2019

For some reason, the simplicity of this design appealed to me in hindsight. It was also my first time exploring threads with 3D printing. (The threads were much more robust than I had initially anticipated.)

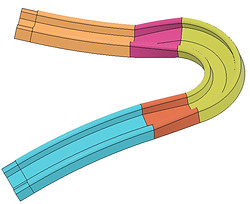

54_Parametric Marble Maze

12/2/2019

The Four Primitives Used to Construct the Three Pieces Below

The Parameters for the Pieces Below

Three Potential Variations of the

Bend Entry-Straight- Bend Turn-Straight-Bend Exit

Configuration

Early Attempts at Constraining 3D Sketches

This project was my most conceptually difficult project of the above. I was trying to create curved marble track pieces with just a few primitives, some parameters, and joints to glue them all together. To make everything completely parameterized, I had to carefully constrain the sketches so changes to the parameters would not affect the model in unanticipated ways. I chose to make 3D sketches to map the path of the primitives and sweep the profile of the marble track along the path. In the end, there were some issues with smoothing out twisting regions so the project was abandoned. However, it was an interesting challenge to test my skills and push the limits of 3D sketches in Fusion 360.